Workshop

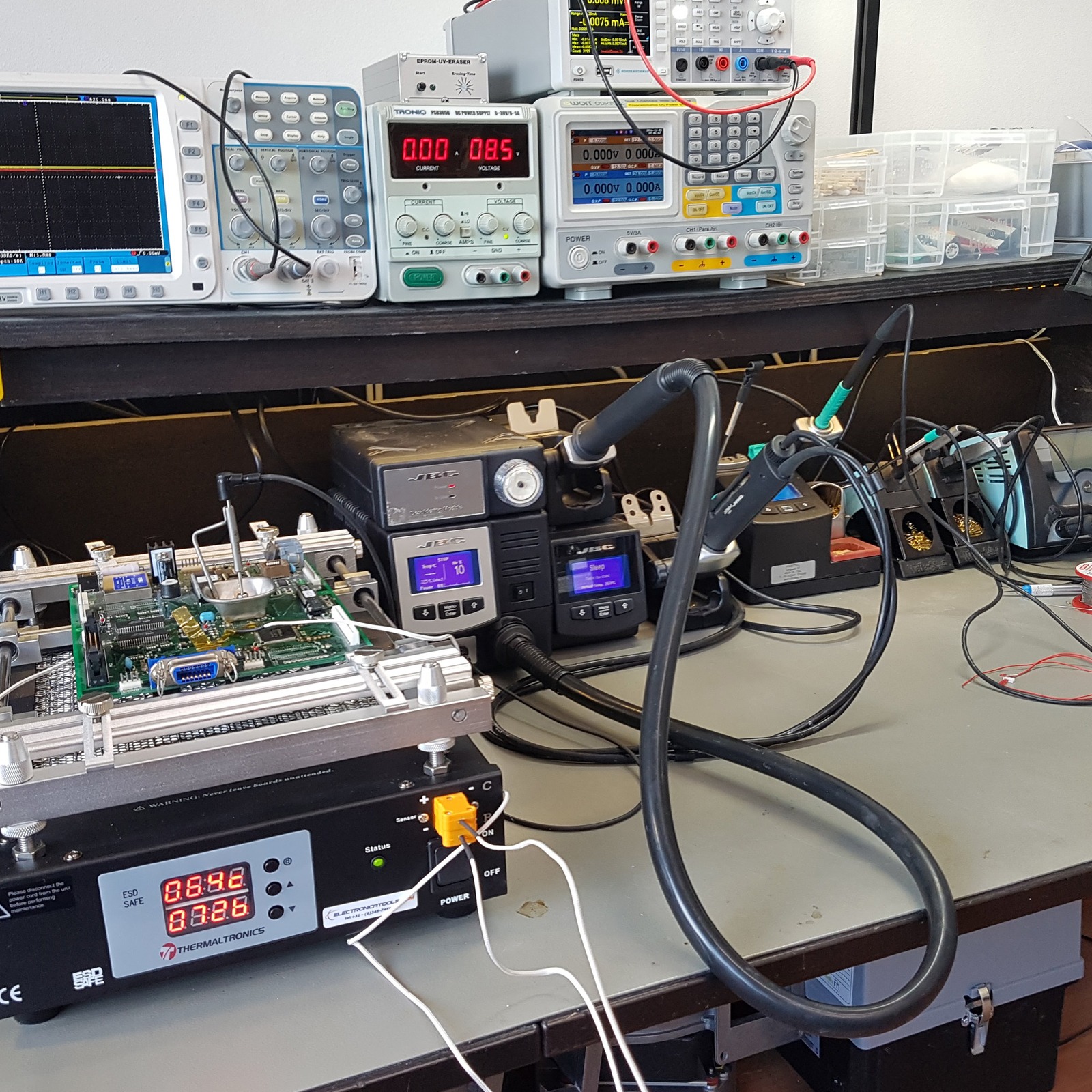

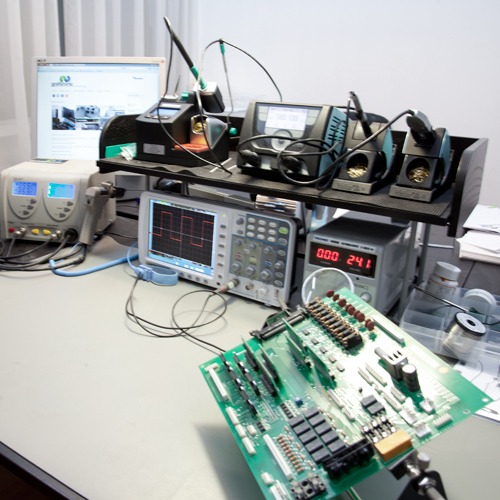

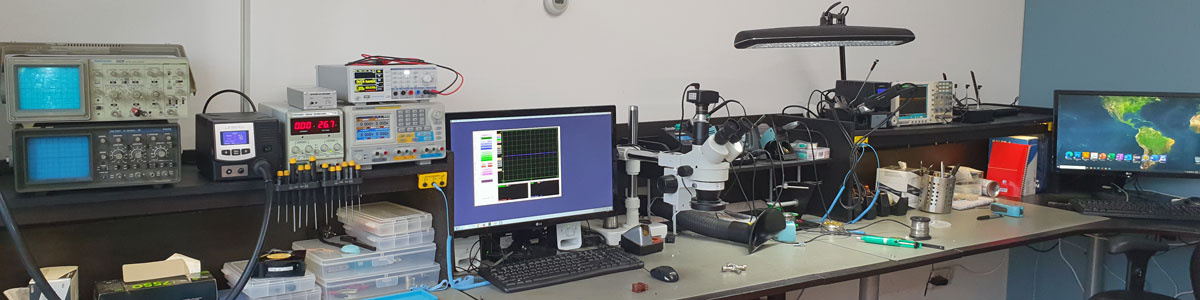

Workshop equipped with lead-free soldering equipment.

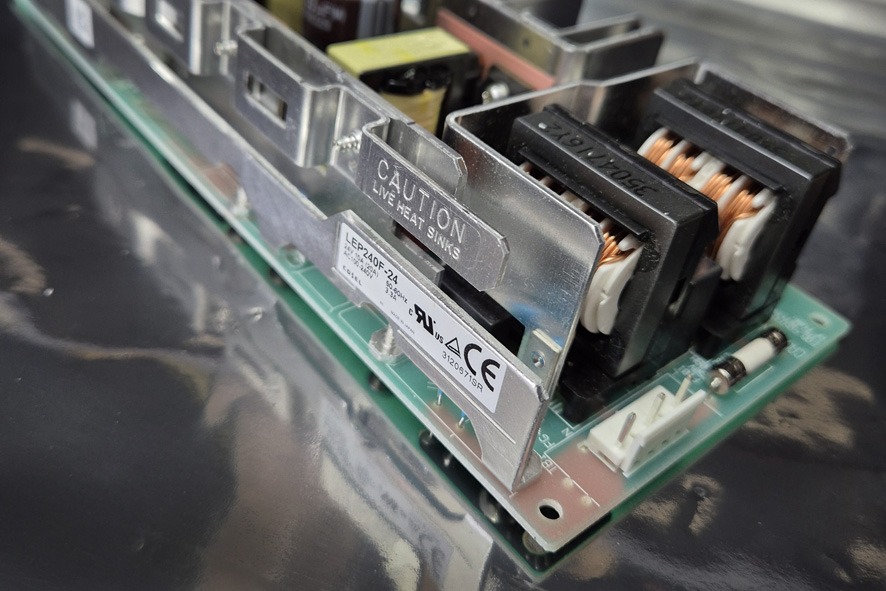

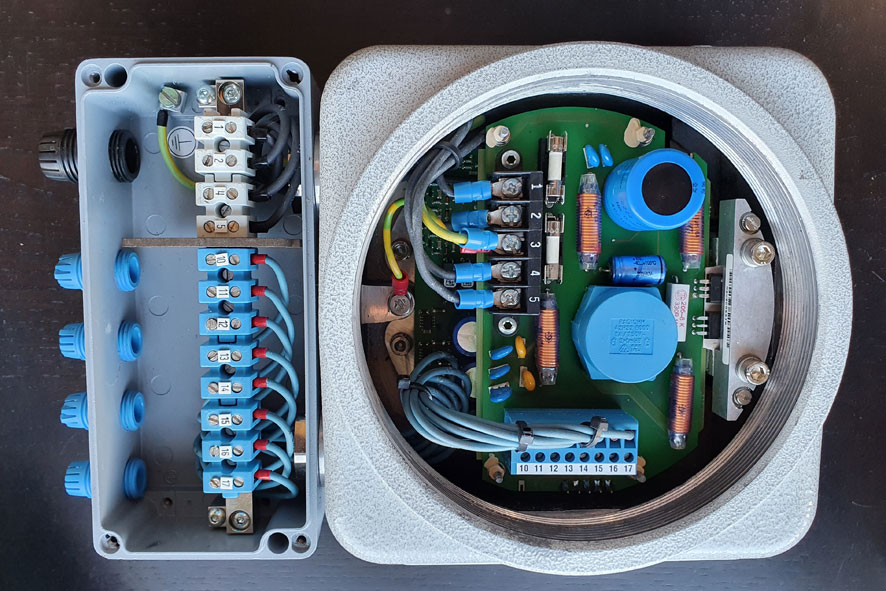

We extended our workshop, specifically for electronics repairs. We recently have invested to accommodate the growing market of SMD components replacement and testing. We perform electronics repairs entirely according to the directives Like IPC, ESD, and RoHS I and II.

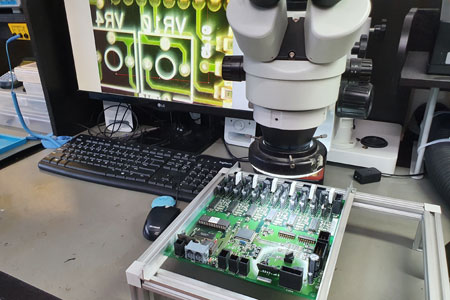

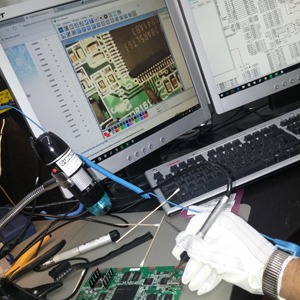

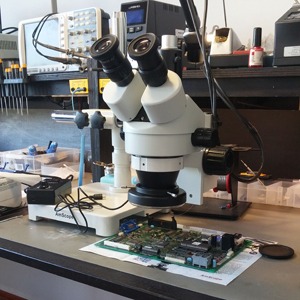

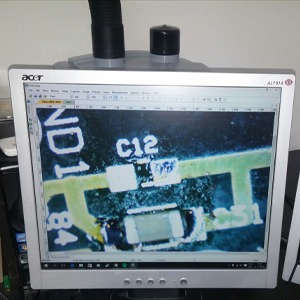

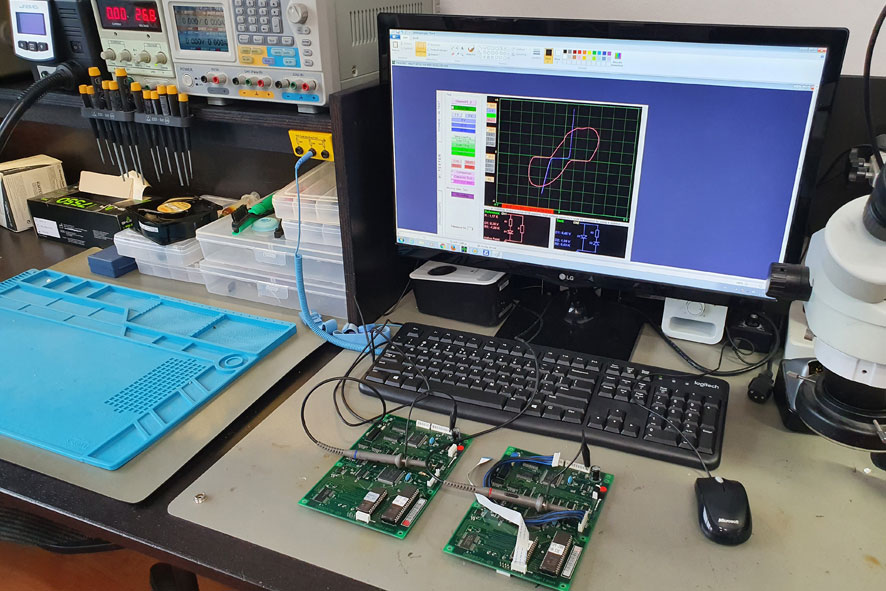

Solder equipment with Microscope

By far the most soldering work we do with the help of a microscope with an HD Camera. So that we can always keep a close eye on the soldering process. And no surprises.

Most of our equipment is now Weller and JBC Advanced. With this equipment, we are able to make easy changes over with various markers for several applications. With this equipment, we can do lead-free soldering and desoldering.

We can also take this soldering and desoldering equipment with us easy for “on-site” repairs.

We also have an extensive workbench including drill column machines. And a large number of tools especially for wiring and developing industrial control cabinets.