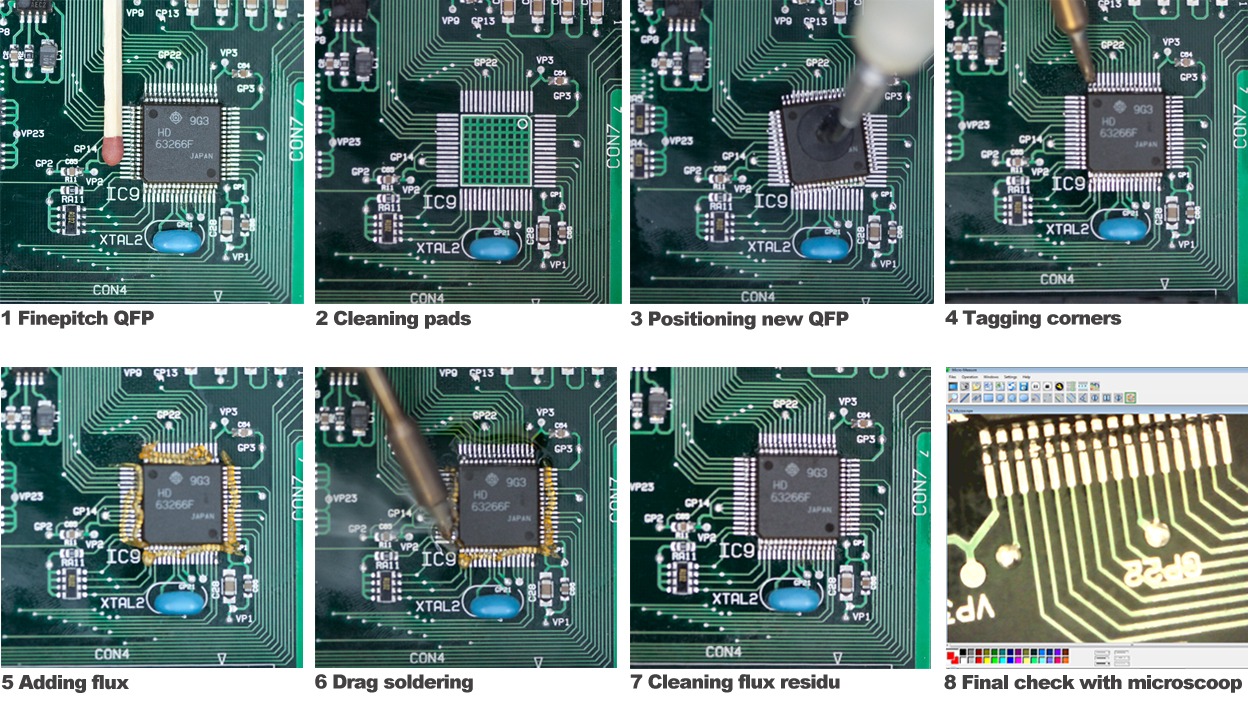

SMT components soldering.

Soldering of SMt components.

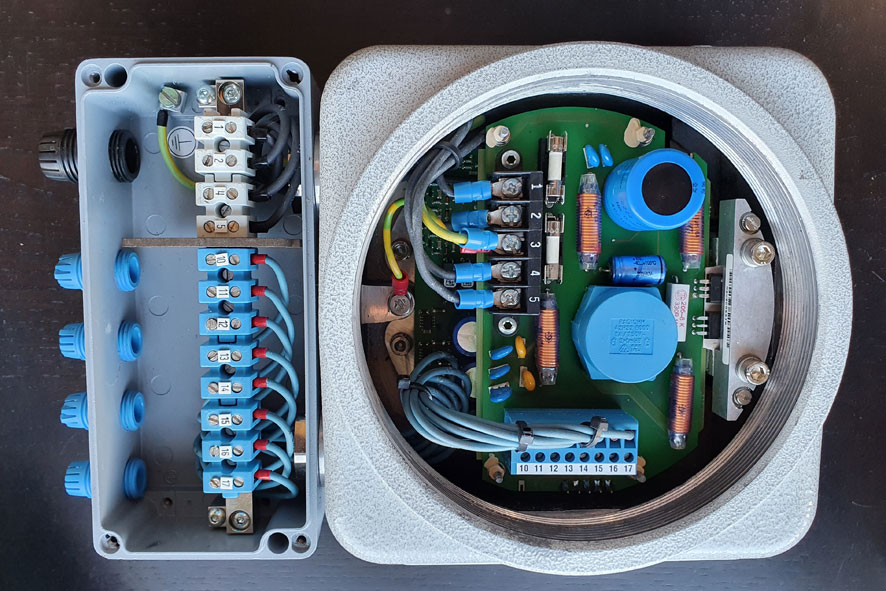

SMT stands for surface mounted technology. Which means the pins of the components are placed on the PC-Board. Instead of through the PC Board on the other side. Like with THT Through hole technology.

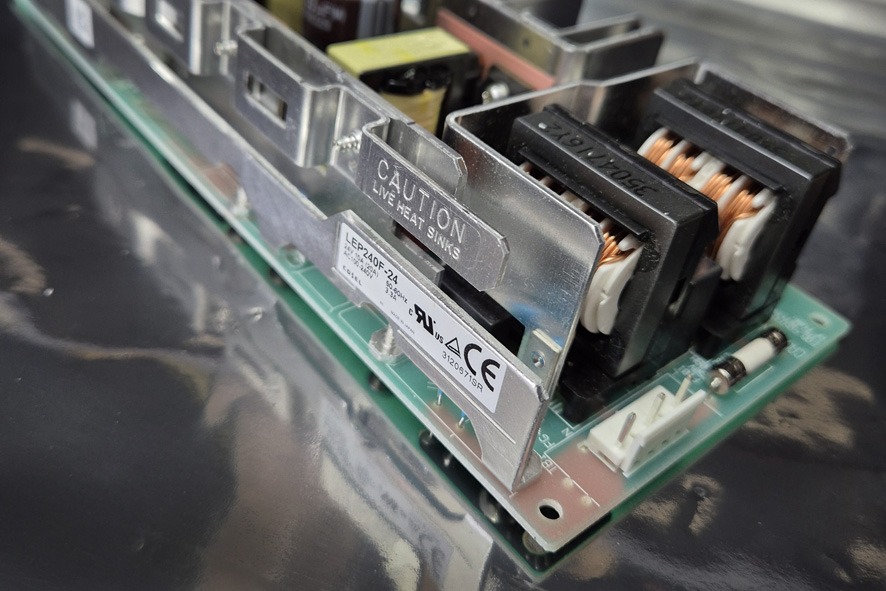

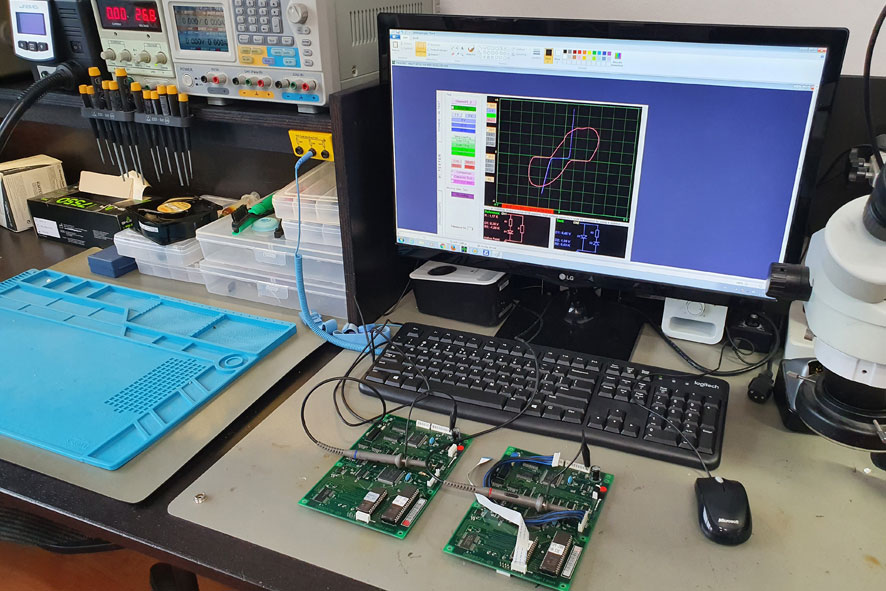

In our workshop we have the possibility to do bth THT and SMT soldering with high performance solder equipment. Al soldering is done. according to the guidelines of Rohs and IPC standard.

We use a microscope with an optional HD camera. In order to be able to assess the soldering work in addition to the view via microscope also via computer dispay..

We also use a preheater when soldering QFP, SOD, SOT, SOIC, PLCC, etc. So that we heat the print evenly and slowly. This is to prevent delamination. And the replaced component is heated at minimum.

We also use hot air and Tweezer soldering irons for soldering SMD components.

IF you have questions about this subject please contact us at anytime.